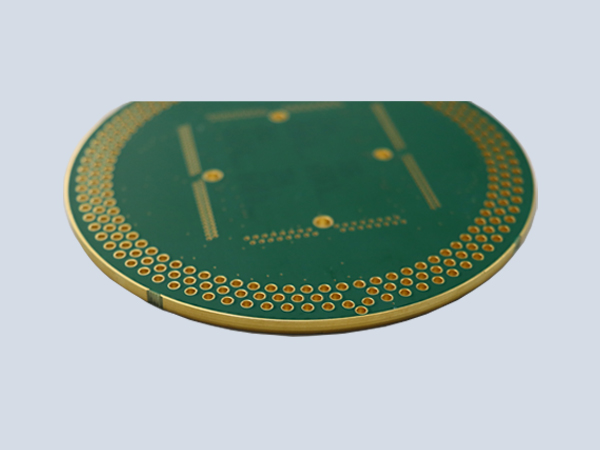

10 - layer PCB circuit board with metal - wrapped edges

Discover the 10 - layer PCB circuit board with metal - wrapped edges, a state - of - the - art solution designed to meet the most demanding requirements in electronics manufacturing. The ten - layer construction offers enhanced functionality and increased design flexibility, while the metal - wrapped edges bring a range of unique advantages. This type of PCB is engineered for applications where high - performance, reliability, and electromagnetic shielding are crucial. Whether it's for advanced communication devices, aerospace electronics, or high - end computing systems, this 10 - layer board with metal - wrapped edges can provide outstanding performance.

Product Description

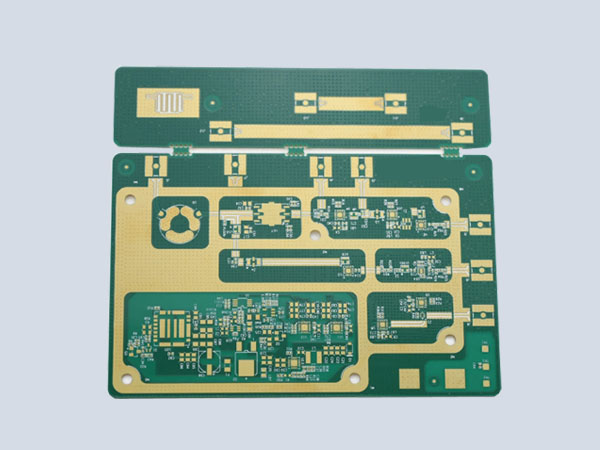

- Ten - Layer Configuration

- The 10 - layer structure of this PCB offers a vast amount of routing space. This allows for the implementation of highly complex circuitry, which is essential for applications that require high - density interconnects. With more layers, designers can separate power and signal layers more effectively, reducing noise and interference. For example, dedicated power planes can be strategically placed between signal layers to ensure stable power delivery to components, while signal layers can be optimized for high - speed data transmission. The additional layers also enable the integration of more components on a single board, leading to more compact and efficient designs.

- Metal - Wrapped Edges

- Electromagnetic Shielding: One of the primary benefits of the metal - wrapped edges is electromagnetic shielding. The metal surrounding the edges of the PCB acts as a barrier, preventing electromagnetic interference (EMI) from entering or escaping the board. This is particularly important in applications where sensitive electronic components need to be protected from external EMI sources, such as in medical devices or military electronics. By reducing EMI, the metal - wrapped edges help improve the overall performance and reliability of the PCB.

- Mechanical Strength: The metal - wrapped edges also enhance the mechanical strength of the PCB. In applications where the board may be subject to vibrations, shocks, or physical stress, such as in automotive or industrial equipment, the added strength provided by the metal wrapping can prevent the board from cracking or breaking. This makes the 10 - layer PCB with metal - wrapped edges more durable and suitable for use in harsh environments.

- Thermal Management: Metal is an excellent conductor of heat. The metal - wrapped edges can assist in dissipating heat generated by components on the PCB. This is especially beneficial in high - power applications, where efficient thermal management is crucial to prevent overheating and ensure the long - term reliability of the components. The metal - wrapped edges can act as heat sinks, helping to transfer heat away from the board and maintain optimal operating temperatures.

- Applications

- Communication Systems: In advanced communication devices, such as 5G base stations and high - speed data routers, the 10 - layer PCB with metal - wrapped edges can support the high - speed data transfer requirements while providing excellent electromagnetic shielding. The complex circuitry needed for signal processing and the need to protect against interference make this type of PCB an ideal choice.

- Aerospace and Defense: Aerospace and defense applications demand highly reliable and rugged electronics. The 10 - layer PCB with metal - wrapped edges can withstand the extreme conditions of space or military operations, including high - temperature variations, vibrations, and electromagnetic radiation. Its ability to handle complex circuitry and provide mechanical strength and EMI shielding makes it suitable for avionics systems, radar equipment, and missile guidance systems.

- High - End Computing: In high - performance computing systems, such as servers and workstations, the 10 - layer PCB with metal - wrapped edges can support the high - density integration of components and the high - speed data transfer between them. The metal - wrapped edges help in managing heat generated by powerful processors and graphics cards, ensuring stable operation even under heavy workloads.

- Reliability and Quality

- Built with high - quality materials, the 10 - layer PCB with metal - wrapped edges is designed to offer exceptional reliability. The manufacturing process involves strict quality control measures to ensure that each layer is precisely fabricated and that the metal - wrapping is of the highest standard. The board is tested for electrical performance, mechanical integrity, and thermal characteristics to guarantee that it meets the rigorous requirements of various industries.

- Customization Options

- Manufacturers offer a wide range of customization options for the 10 - layer PCB with metal - wrapped edges. Whether you need specific component placements to fit a unique form - factor, additional layers for more complex functions, or customized metal - wrapping designs to meet specific EMI or thermal requirements, the PCB can be tailored to your exact needs. This flexibility allows you to create a PCB that is perfectly optimized for your application, whether it's a new product development or an upgrade to an existing system.