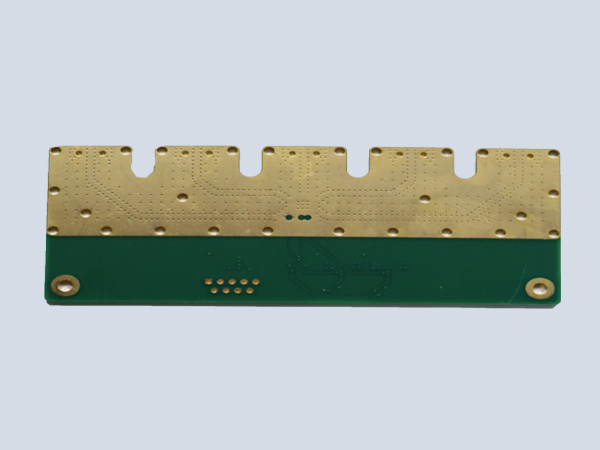

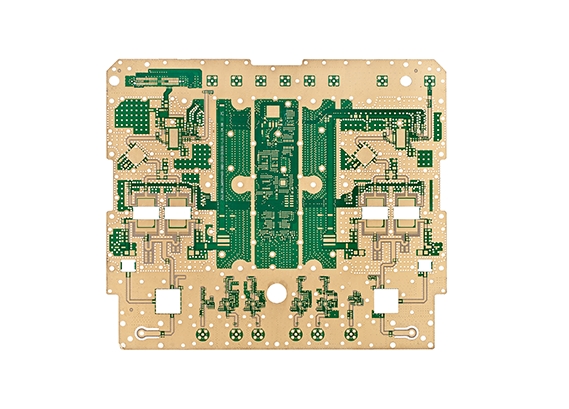

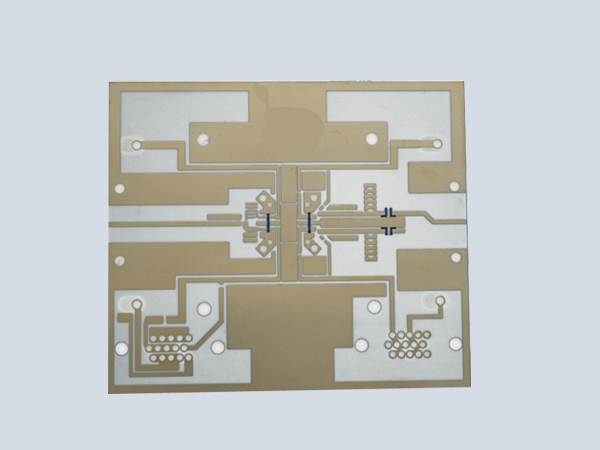

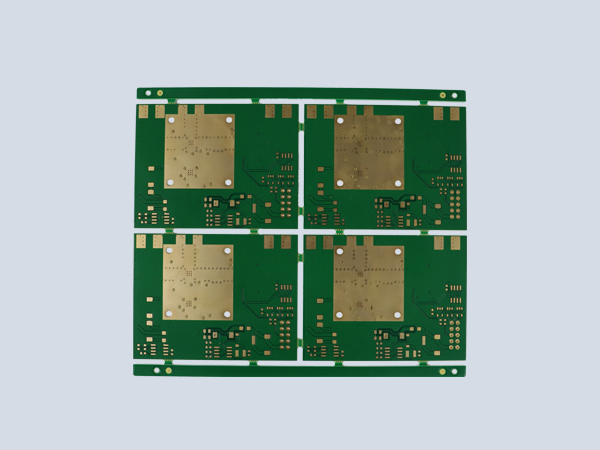

Hybrid Laminated PCB Circuit Board

Unveil the Hybrid Laminated PCB Circuit Board, a revolutionary and adaptable solution in the PCB domain. This board ingeniously combines diverse materials and laminating techniques, presenting a plethora of unique benefits. Engineered to satisfy the multifarious demands of industries spanning from consumer electronics to industrial machinery, where a harmonious blend of performance, cost - efficiency, and specialized functions is essential. Be it the development of state - of - the - art smartphones, intricate industrial control setups, or sophisticated medical apparatuses, the Hybrid Laminated PCB Circuit Board can be customized precisely to your needs.

- Innovative Hybrid Lamination Approach

- Material Synergy: Hybrid laminated PCBs artfully combine materials like common FR - 4 laminates with high - end materials such as polyimide or ceramic. This union harnesses the best attributes of each material. For instance, polyimide layers can endow the board with enhanced flexibility and heat resistance, while FR - 4 offers a cost - effective foundation for general circuit functions. As a result, the PCB can endure a wide gamut of operating temperatures and mechanical strains.

- Superior Electrical Characteristics: Through meticulous selection and lamination of materials, the electrical properties of the PCB are optimized. The board can achieve superior signal integrity, lower impedance, and reduced signal interference. In high - speed data - intensive applications, like data centers with massive data transfer requirements, the hybrid lamination ensures seamless and accurate signal transmission across the board.

- Diverse Application Spectrum

- Consumer Electronics Realm: In consumer electronics such as smartphones and tablets, hybrid laminated PCBs play a pivotal role in packing more functionality into a compact footprint. The ability to combine materials enables the integration of components like high - performance processors, energy - efficient batteries, and advanced wireless modules. The board's flexibility can also be leveraged to design novel form - factors, like curved displays in some top - tier smartphones.

- Industrial Machinery Sector: For industrial machinery, hybrid laminated PCBs are crafted to be robust and reliable. In factory automation systems, they can withstand harsh environmental factors including vibrations, temperature fluctuations, and electromagnetic interference. The combination of materials provides excellent mechanical strength and electrical insulation, ensuring the long - term, trouble - free operation of the equipment.

- Medical Equipment Field: In the medical field, hybrid laminated PCBs are utilized in devices like portable patient monitors and diagnostic tools. Precise control of electrical properties and the capacity to integrate multiple functions on a single board are of utmost importance. For example, in a portable electrocardiogram (ECG) monitor, the PCB needs to accurately measure and transmit the patient's electrical signals, and the hybrid lamination aids in achieving high - precision signal processing.

- Cost - Efficiency Edge

- Optimal Material Deployment: Hybrid laminated PCBs offer a cost - effective solution by deploying materials judiciously. Instead of using expensive high - performance materials throughout the board, manufacturers can strategically position them only where necessary. For example, in cost - sensitive consumer electronics, high - speed data transfer or heat - resistant areas can be constructed with high - performance materials, while the rest of the board can utilize more affordable FR - 4.

- Reduced Assembly Expenses: The capacity to integrate more components on a single hybrid laminated PCB reduces the need for multiple boards and external connectors. This simplifies the assembly process and curtails overall production costs. In large - scale manufacturing, these cost savings can be substantial.

- Reliability and Quality Assurance

- Rigorous Manufacturing Regime: The production of hybrid laminated PCBs adheres to strict quality control protocols. Each material layer is carefully chosen, prepared, and laminated to ensure a robust bond and precise circuitry alignment. The boards undergo comprehensive testing, including electrical, mechanical stress, and environmental testing. This ensures that the final product can meet the exacting reliability standards of diverse industries.

- Long - lasting Durability: Thanks to the combination of top - notch materials and a well - engineered lamination process, hybrid laminated PCBs boast excellent long - term durability. They can endure repeated thermal cycling, mechanical vibrations, and exposure to various environmental elements, making them ideal for applications where the PCB must operate dependably over an extended period.

- Customization Capabilities

- Tailored to Your Design Blueprint: Manufacturers provide a wide array of customization options for hybrid laminated PCBs. Whether you require specific material combinations to meet your product's performance criteria, customized layer arrangements for complex circuitry, or unique form - factors to fit your device's enclosure, the PCB can be designed and fabricated to your precise specifications. This flexibility empowers you to create a PCB that is perfectly tailored to your product, be it a new consumer electronics innovation or an upgrade to an industrial system.