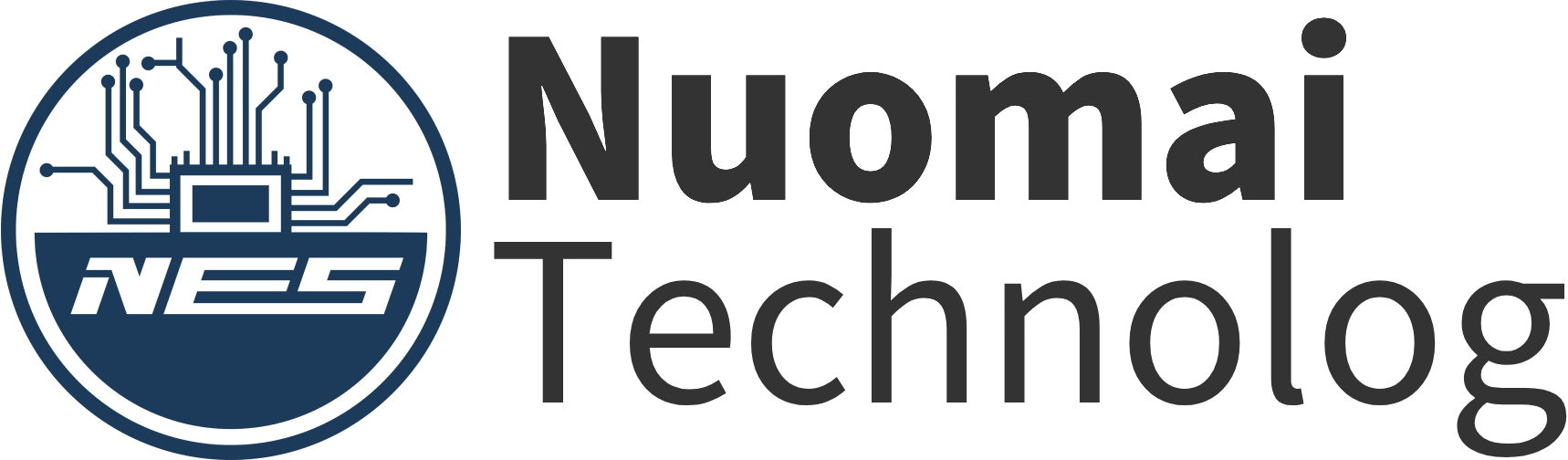

Multi - layer Rigid - Flex Circuit Board

Discover the Multi - layer Rigid - Flex Circuit Board, a remarkable and highly adaptable solution in the field of printed circuit boards. This advanced board combines the rigidity of traditional PCB layers with the flexibility of specialized flex circuits, offering a unique blend of features. Engineered to meet the complex demands of a wide range of industries, from aerospace and automotive to wearable electronics and medical devices, it provides an ideal balance between mechanical robustness, electrical performance, and design versatility. Whether you're developing lightweight and compact avionics systems, advanced automotive infotainment devices, or innovative wearable health monitors, the Multi - layer Rigid - Flex Circuit Board can be customized to precisely fit your requirements.

- Innovative Multi - layer Rigid - Flex Design

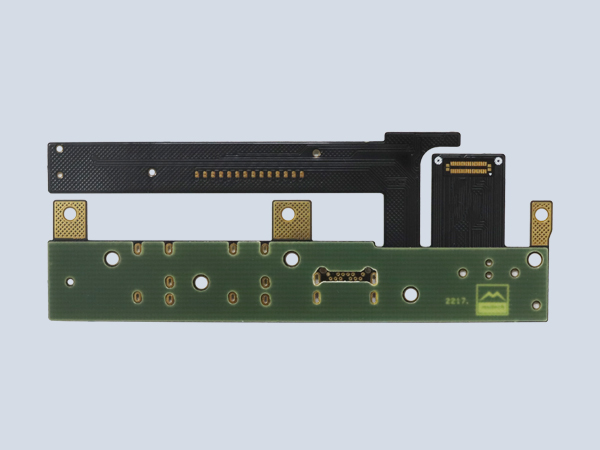

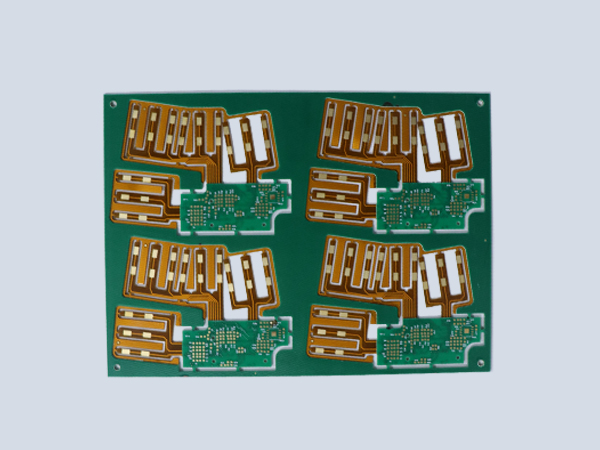

- Combination of Rigid and Flex Layers: The multi - layer structure of this board incorporates both rigid PCB layers, typically made of materials like FR - 4 for stability and mechanical support, and flexible layers, often constructed from polyimide films. The rigid layers are excellent for mounting components that require a sturdy base, such as large integrated circuits and connectors. The flexible layers, on the other hand, can be bent or flexed to fit into tight spaces or conform to unique shapes. For example, in a wearable fitness tracker, the flexible part of the board can wrap around the user's wrist, while the rigid part holds the display and main processing components.

- Enhanced Interconnectivity: The integration of multiple layers in a rigid - flex design allows for more complex and efficient interconnectivity. Signals can be routed through different layers, both rigid and flex, to reach various components. This not only increases the number of possible connections but also helps in reducing signal interference. In aerospace applications, where numerous sensors and actuators need to communicate with a central processing unit, the multi - layer rigid - flex board enables seamless data transfer between these components.

- Versatile Applications

- Aerospace Industry: In aerospace, the Multi - layer Rigid - Flex Circuit Board is used in avionics systems. The board's ability to withstand extreme environmental conditions, such as high altitudes, temperature variations, and vibrations, makes it suitable for use in aircraft and satellites. The lightweight nature of the board, due to the combination of rigid and flex layers, also helps in reducing the overall weight of the avionics equipment, which is crucial for fuel efficiency and performance.

- Automotive Sector: In the automotive industry, these boards are utilized in advanced driver - assistance systems (ADAS), in - vehicle infotainment systems, and electric vehicle battery management systems. The flexibility of the board allows for easy installation in tight spaces within the vehicle, such as behind dashboards or in door panels. The rigid parts can support heavy - duty components like high - power processors used in ADAS for real - time data processing.

- Wearable Electronics: Wearable devices, such as smartwatches and fitness bands, rely on multi - layer rigid - flex circuit boards to achieve a compact and comfortable design. The flexible sections can conform to the shape of the body, while the rigid sections house the essential components like batteries, displays, and wireless communication modules. This combination enables the creation of sleek and ergonomic wearable products.

- Medical Devices: In medical devices, such as portable patient monitors and minimally invasive surgical tools, multi - layer rigid - flex circuit boards play a vital role. The boards can be designed to be biocompatible and can withstand the sterilization processes required in the medical field. The precise routing of electrical signals through multiple layers is crucial for accurate data acquisition and transmission, for example, in a portable electroencephalogram (EEG) monitor that needs to detect and record the brain's electrical activity.

- Cost - Effectiveness

- Optimized Material Usage: By combining rigid and flex layers, manufacturers can use materials more efficiently. High - cost materials are used only where necessary, such as in the flexible layers for their specific properties, while more cost - effective rigid materials are used for areas that require mechanical strength. This targeted use of materials reduces overall production costs without sacrificing performance.

- Reduced Assembly Complexity: The integration of multiple functions on a single multi - layer rigid - flex board reduces the need for multiple separate boards and connectors. This simplifies the assembly process, saving both time and labor costs. In large - scale manufacturing, these savings can be significant, making the product more cost - competitive in the market.

- Reliability and Quality

- Rigorous Manufacturing Process: The manufacturing of multi - layer rigid - flex circuit boards involves strict quality control measures. Each layer, whether rigid or flex, is carefully fabricated and inspected. The bonding between the rigid and flex layers is also closely monitored to ensure a strong and reliable connection. The boards undergo comprehensive testing, including electrical testing to verify signal integrity, mechanical stress testing to ensure durability under bending and vibration, and environmental testing to check their performance in different conditions.

- Long - Term Durability: The combination of high - quality materials and a well - engineered manufacturing process results in a board with excellent long - term durability. The rigid - flex board can withstand repeated bending, thermal cycling, and exposure to various environmental factors, ensuring reliable operation over an extended period. This makes it suitable for applications where the board needs to function consistently for years, such as in industrial control systems.

- Customization Options

- Tailored to Your Exact Needs: Manufacturers offer a wide range of customization options for multi - layer rigid - flex circuit boards. Whether you need specific layer stack - ups to optimize electrical performance, customized shapes for unique form - factors, or the integration of special components, the board can be designed and fabricated to your exact specifications. This flexibility allows you to create a circuit board that is perfectly tailored to your product, whether it's a new aerospace prototype or a consumer - facing wearable device.