Customization of FPC Rigid - Flex Boards

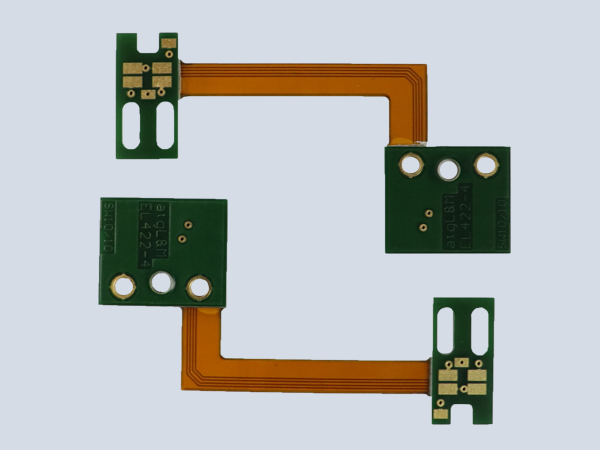

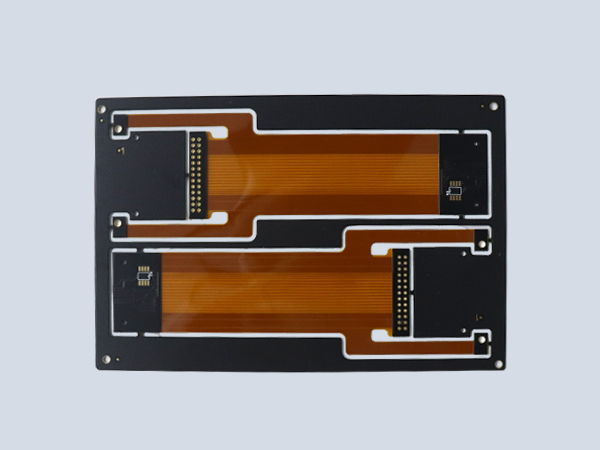

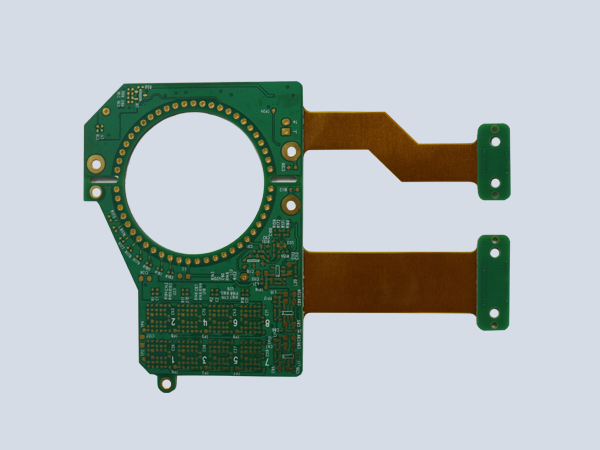

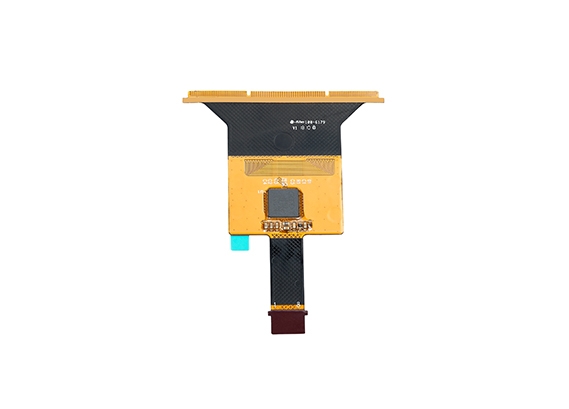

Discover the customization services for FPC Rigid - Flex Boards, a tailored solution designed to meet the unique requirements of various industries. FPC (Flexible Printed Circuit) Rigid - Flex Boards combine the flexibility of flexible circuits with the rigidity of traditional PCBs, offering a versatile platform. Our customization services are engineered to provide you with boards that are not only high - performance but also precisely fit your specific application needs. Whether you're in the electronics, automotive, or medical field, our customized FPC Rigid - Flex Boards can enhance your product's functionality and design.

Product Description

- Customization Capabilities

- Layer Configuration Customization: We offer the flexibility to customize the layer stack - up of FPC Rigid - Flex Boards. You can choose the number of rigid and flex layers according to your electrical and mechanical requirements. For example, in a complex electronic device with high - speed data transfer needs, additional signal layers can be added in the rigid part, while the flexible layers can be optimized for space - saving and bend - ability. This allows for the creation of a board that can handle multiple functions efficiently.

- Component Placement and Routing: Our customization service enables precise component placement and routing. We work closely with you to ensure that components such as integrated circuits, connectors, and sensors are placed in the most optimal positions on the board. The routing of traces can be customized to minimize signal interference and ensure smooth signal transmission. In automotive applications, where components need to be placed in specific locations for safety and functionality reasons, our customized routing can meet these exacting standards.

- Shape and Size Customization: FPC Rigid - Flex Boards can be customized in terms of shape and size. Whether you need a board with a unique curved shape to fit into a compact device or a larger - sized board to accommodate more components, we can fulfill your requirements. In wearable electronics, for instance, the board can be shaped to conform to the contours of the body, providing a comfortable and ergonomic design.

- Industry - Specific Customization

- Electronics Industry: In the electronics industry, customized FPC Rigid - Flex Boards are used in smartphones, tablets, and laptops. We can customize the boards to support high - speed data transfer between components, such as between the processor and the display. The flexibility of the boards allows for the creation of thinner and more lightweight devices, enhancing the overall user experience.

- Automotive Industry: For the automotive industry, our customized FPC Rigid - Flex Boards are used in advanced driver - assistance systems (ADAS), in - vehicle infotainment systems, and electric vehicle battery management systems. We can design the boards to be resistant to vibrations, temperature variations, and electromagnetic interference, ensuring reliable performance in harsh automotive environments.

- Medical Industry: In the medical field, customized FPC Rigid - Flex Boards are crucial for devices like portable patient monitors, surgical robots, and implantable medical devices. We can ensure that the boards are biocompatible and can withstand sterilization processes. The precise customization of electrical traces and component placement is essential for accurate data acquisition and transmission in medical applications.

- Quality Assurance in Customization

- Advanced Manufacturing Technology: We use state - of - the - art manufacturing technology to ensure the highest quality in customized FPC Rigid - Flex Boards. Our manufacturing process includes precision etching, lamination, and soldering techniques. Each step is carefully monitored to ensure that the customized boards meet the strictest quality standards.

- Comprehensive Testing: All customized FPC Rigid - Flex Boards undergo comprehensive testing. This includes electrical testing to verify signal integrity, mechanical testing to ensure the durability of the flex and rigid parts, and environmental testing to check the board's performance under different conditions such as temperature, humidity, and vibration. Only boards that pass all these tests are delivered to you.

- Benefits of Customization

- Optimized Performance: Customized FPC Rigid - Flex Boards are designed to optimize the performance of your product. By tailoring the board to your specific application, you can achieve better electrical performance, reduced power consumption, and improved reliability.

- Cost - Effectiveness in the Long Run: Although customization may seem like an additional cost initially, it can lead to long - term cost - savings. A well - customized board can reduce the need for additional components or complex assembly processes, ultimately lowering the overall production cost of your product.

- Competitive Edge: With customized FPC Rigid - Flex Boards, you can gain a competitive edge in the market. Your product can stand out with its unique design and enhanced functionality, attracting more customers and increasing your market share.