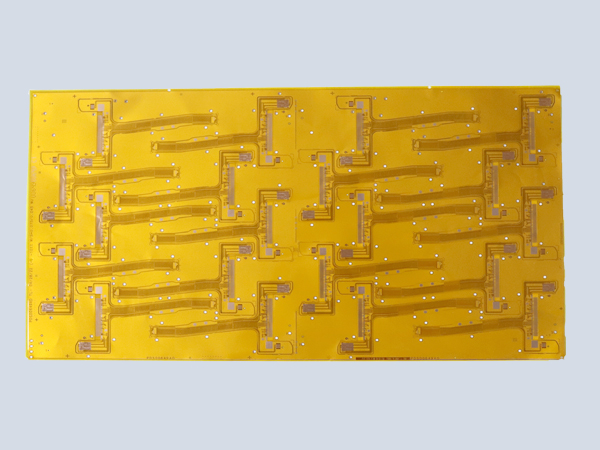

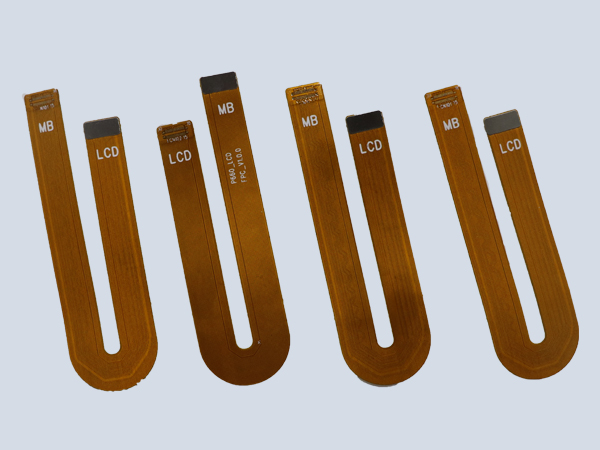

Flexible Printed Circuit (FPC) Board

Explore the Flexible Printed Circuit (FPC) Board, a revolutionary solution in the electronics manufacturing landscape. FPC boards are designed with a high - degree of flexibility, enabling them to adapt to various shapes and applications. These boards have transformed industries by providing a compact, lightweight, and reliable alternative to traditional rigid circuit boards. Whether you're involved in the production of consumer electronics, automotive systems, or medical devices, FPC boards offer a wealth of advantages that can enhance your product's performance and design.

- Unique Flexible Design

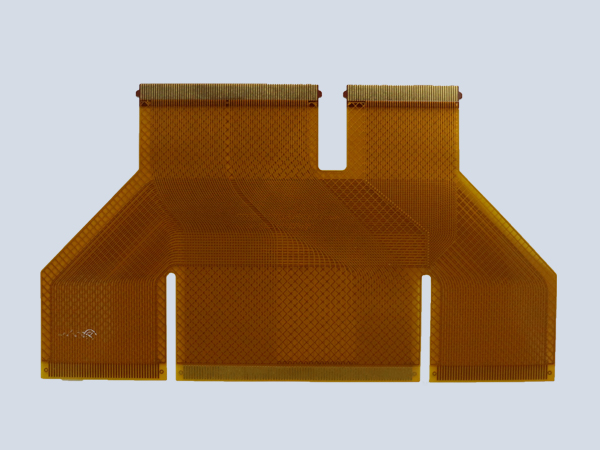

- Material Composition: FPC boards are typically made from flexible materials such as polyimide or polyester films. Polyimide, for example, offers excellent heat resistance, chemical stability, and mechanical strength, making it suitable for a wide range of applications. These materials can be bent, twisted, or folded without significant damage to the electrical traces, allowing for creative and space - saving designs.

- Thin and Lightweight: The flexibility of FPC boards is accompanied by their thin and lightweight nature. This makes them ideal for applications where space and weight are critical factors. In smartphones, for instance, FPC boards can be used to connect the display to the main board, reducing the overall thickness and weight of the device. The thin profile also enables better heat dissipation, contributing to improved device performance.

- Electrical Performance

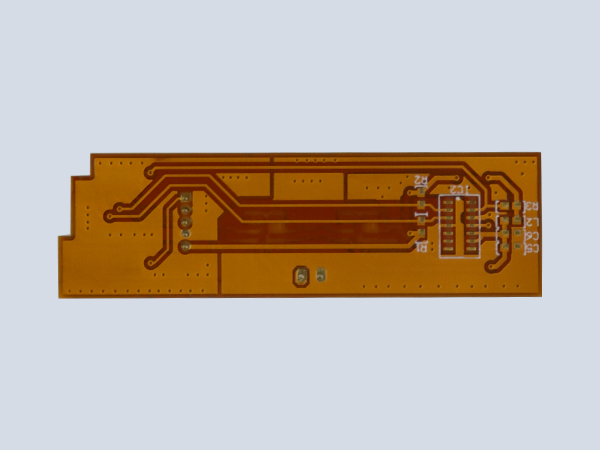

- Precise Circuit Routing: FPC boards allow for precise circuit routing, which is essential for high - speed data transfer and complex electrical connections. The manufacturing process enables the creation of fine - pitch traces and small vias, facilitating the integration of multiple components on a single board. In high - end computing devices, FPC boards can handle high - speed signals between processors, memory modules, and other components, ensuring smooth and efficient operation.

- Low Signal Loss: The materials used in FPC boards are carefully selected to minimize signal loss. This is crucial in applications such as wireless communication devices, where accurate signal transmission is vital. FPC boards can maintain signal integrity even at high frequencies, enabling reliable data transfer over long distances within the device.

- Applications

- Consumer Electronics: FPC boards are widely used in consumer electronics, including smartphones, tablets, laptops, and wearables. In smartwatches, for example, the flexible nature of the board allows it to wrap around the wrist comfortably while connecting various components such as the display, battery, and sensors. The ability to conform to irregular shapes also enables the creation of more stylish and ergonomic designs.

- Automotive Industry: In the automotive sector, FPC boards are employed in a variety of applications, such as in - vehicle infotainment systems, advanced driver - assistance systems (ADAS), and lighting systems. They can withstand the harsh environmental conditions in cars, including vibrations, temperature variations, and exposure to moisture. FPC boards are also used to connect multiple sensors and actuators in a compact and reliable manner, contributing to the overall safety and functionality of the vehicle.

- Medical Devices: In the medical field, FPC boards play a crucial role in devices such as portable patient monitors, surgical instruments, and implantable medical devices. Their biocompatibility and flexibility make them suitable for applications where the device needs to be in close contact with the body. For example, in a flexible endoscope, the FPC board can be used to transmit high - quality images from the camera at the tip to the control unit, while being flexible enough to navigate through the body's narrow passages.

- Reliability and Durability

- Robust Manufacturing Process: The manufacturing of FPC boards involves strict quality control measures. The boards are subjected to various tests, including electrical testing, mechanical stress testing, and environmental testing. Precision etching, lamination, and soldering techniques are used to ensure the integrity of the electrical traces and the overall durability of the board.

- Long - Term Performance: FPC boards are designed to provide long - term reliable performance. They can withstand repeated bending and flexing over an extended period without significant degradation in electrical performance. This makes them suitable for applications where the board needs to function continuously for years, such as in industrial control systems.

- Customization Options

- Tailored to Your Needs: Manufacturers offer a wide range of customization options for FPC boards. Whether you need a specific shape, size, or layer configuration, the boards can be customized to meet your exact requirements. You can also choose the type of materials, surface finishes, and components to be integrated onto the board. This flexibility allows you to create a FPC board that is perfectly suited to your product, whether it's a new consumer electronics innovation or a medical device upgrade.