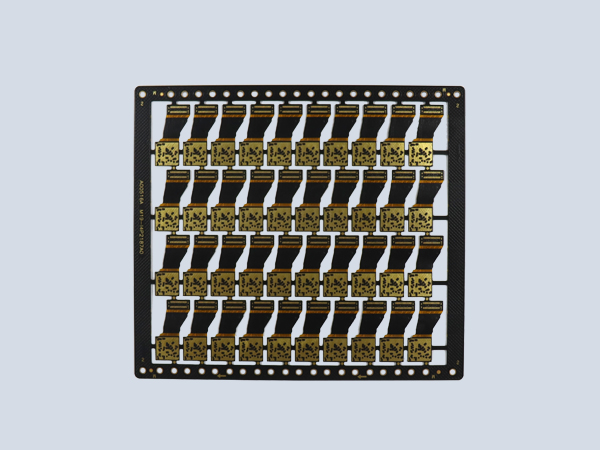

FPC Flexible Board for Camera Module

Discover the FPC Flexible Board for Camera Module, a specialized and essential component in the world of modern imaging technology. Engineered specifically for camera modules, this flexible printed circuit (FPC) board offers a unique set of advantages that are crucial for ensuring high - quality image capture and seamless integration within various devices. Whether it's in smartphones, tablets, digital cameras, or even in emerging applications like drones and security cameras, the FPC Flexible Board for Camera Module plays a pivotal role in enhancing the performance and functionality of the camera system.

- Design for Camera Module Compatibility

- Precise Component Placement: The FPC board is designed with precision to accommodate the specific components of a camera module. This includes the image sensor, lens, and associated control circuitry. The layout of the board ensures that these components are placed in the optimal positions to minimize signal interference and maximize the efficiency of data transfer between them. For example, the traces connecting the image sensor to the processing unit are carefully routed to ensure fast and accurate transmission of image data.

- Flexible Connectivity: The flexibility of the FPC board allows for easy connection between different parts of the camera module and the main device's motherboard. It can be bent or curved to fit into tight spaces, which is especially important in compact devices like smartphones where space is at a premium. This flexibility also enables the camera module to be positioned in various orientations, providing more design freedom for device manufacturers.

- Electrical Performance for Imaging

- High - Speed Data Transmission: Camera modules require high - speed data transfer to capture and process high - resolution images. The FPC board is engineered to support rapid data transmission rates. The materials used in the board, such as high - quality copper traces and low - dielectric - constant insulating materials, are chosen to minimize signal loss and crosstalk. In high - end smartphones with advanced camera systems capable of shooting 4K or even 8K videos, the FPC board ensures that the large amount of image data can be quickly transferred from the sensor to the processor without degradation.

- Low Noise and Interference Resistance: To achieve clear and sharp images, the FPC board is designed to resist electrical noise and interference. Special shielding techniques may be employed to protect the sensitive image sensor from external electromagnetic interference. This is crucial in environments where there are multiple electronic components operating simultaneously, such as in a crowded smartphone motherboard. By reducing noise, the FPC board helps to improve the overall image quality, resulting in clearer and more detailed photos and videos.

- Applications

- Smartphones: In smartphones, the FPC Flexible Board for Camera Module is a key component. It enables the integration of high - quality camera systems in a compact and lightweight design. With the increasing demand for better camera performance in smartphones, such as improved low - light photography and optical image stabilization, the FPC board's ability to support high - speed data transfer and reliable connectivity is essential.

- Tablets and Laptops: Tablets and laptops also rely on FPC boards for their camera modules. These boards allow for the integration of cameras in thin and sleek form - factors. In laptops, the FPC board can be used to connect the webcam to the main board, ensuring smooth video conferencing and other imaging - related functions.

- Digital Cameras: In traditional digital cameras, the FPC board is used to connect the camera's various components, including the image sensor, lens control unit, and display. It helps in achieving high - quality image capture and quick data processing, which are the hallmarks of professional - grade digital cameras.

- Emerging Applications: In emerging applications like drones and security cameras, the FPC Flexible Board for Camera Module is equally important. Drones require lightweight and flexible components to ensure stable flight and high - quality aerial imaging. Security cameras, on the other hand, need reliable and compact camera modules that can be easily installed in various locations, and the FPC board enables this with its flexible design and excellent electrical performance.

- Reliability and Durability

- Robust Manufacturing Process: The manufacturing of the FPC board for camera modules involves strict quality control measures. Precision etching techniques are used to create fine - pitch traces, and high - temperature lamination processes are employed to ensure a strong bond between the layers. The board is then subjected to comprehensive testing, including electrical testing, mechanical stress testing, and environmental testing. This ensures that the board can withstand the rigors of normal use, such as repeated bending during device assembly and operation in different temperature and humidity conditions.

- Long - Term Performance: Designed for long - term use, the FPC board can maintain its electrical and mechanical properties over an extended period. It can withstand repeated bending and flexing without significant degradation in performance. This is important in applications where the camera module may be subject to movement or vibration, such as in a handheld device or a moving drone. The long - term reliability of the FPC board ensures that the camera module continues to function optimally, providing consistent image quality over time.

- Customization Options

- Tailored to Your Requirements: Manufacturers offer a wide range of customization options for the FPC Flexible Board for Camera Module. Whether you need a specific shape to fit a unique camera module design, additional layers for more complex circuitry, or customized surface finishes to improve adhesion or corrosion resistance, the board can be customized to meet your exact needs. You can also choose the type of materials used in the board to optimize its performance for your specific application. This flexibility allows you to create an FPC board that is perfectly suited to your camera module, whether it's for a new smartphone model or an advanced security camera system.