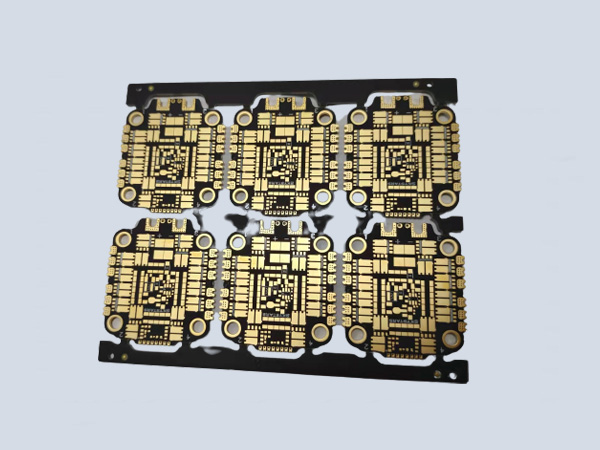

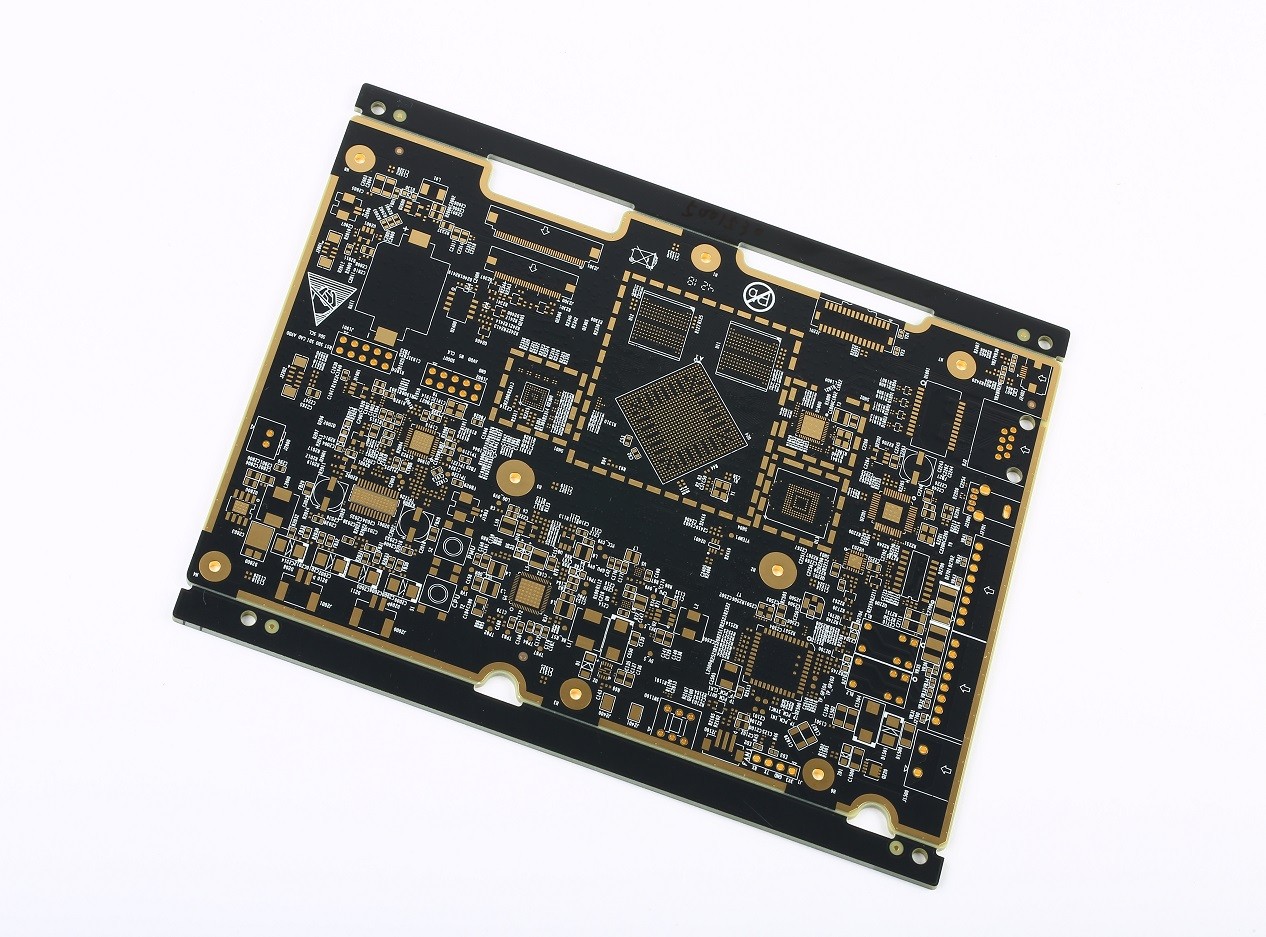

8 - layer Second - Order Drone Circuit Board

Explore the 8 - layer Second - Order Drone Circuit Board, an advanced and high - performance solution crafted specifically for the demanding requirements of drone technology. With its unique eight - layer construction and second - order design features, this circuit board offers a plethora of advantages. Engineered to support the complex systems within drones, it enables seamless operation, efficient power management, and reliable data transfer. Whether you're involved in the development of consumer - grade drones for photography and videography or industrial - use drones for tasks like surveillance and delivery, this 8 - layer second - order circuit board can significantly enhance the performance and functionality of your drone.

- Eight - Layer Architecture

- Abundant Routing Space: The 8 - layer structure provides an extensive amount of routing space. This allows for the implementation of highly intricate circuitry, which is essential for the diverse components and functions within a drone. Designers can separate power and signal layers more effectively, reducing interference and ensuring optimal signal integrity. For example, dedicated power planes can be placed between signal layers to supply stable power to components such as motors, flight controllers, and communication modules. The extra layers also enable more complex signal routing, which is crucial for high - speed data transfer between different parts of the drone system.

- Enhanced Component Integration: With eight layers, more components can be integrated onto a single board. This not only leads to a more compact design but also reduces the need for external connectors and cables, which can introduce signal degradation and increase weight. In a drone, where space and weight are critical factors for flight performance, the ability to integrate components like sensors, processors, and power regulators on a single 8 - layer board is highly advantageous. It helps in creating a more streamlined and efficient drone design.

- Second - Order Design Features

- Advanced Via Configuration: Second - order design in this circuit board involves a more complex via structure. Blind vias that connect outer layers to inner layers and buried vias that connect inner layers to other inner layers are used in a strategic manner. This reduces the overall board size and improves routing efficiency. For instance, in a drone's flight control system, the use of second - order vias allows for a more compact layout of components, which in turn helps in reducing the weight of the drone. The optimized via configuration also minimizes signal loss, ensuring accurate and fast communication between components.

- Improved Signal Integrity at High Frequencies: The second - order design is optimized to handle high - frequency signals, which are common in drone communication systems (such as Wi - Fi, Bluetooth, or radio - frequency links for remote control). By carefully controlling the impedance of the traces and reducing the length of signal paths through the use of appropriate vias, the circuit board can maintain excellent signal integrity even at high frequencies. This is crucial for reliable communication between the drone and its operator, as well as for the seamless transfer of data from on - board sensors to the ground station.

- Applications in Drones

- Consumer - Grade Drones: In consumer - grade drones used for photography and videography, the 8 - layer second - order circuit board plays a vital role. It supports the high - resolution cameras and gimbal systems, ensuring smooth and stable video capture. The board's ability to handle the data transfer from the camera to the storage device or for live streaming is essential for providing users with high - quality visual content. Additionally, it manages the power distribution to the motors and other components, ensuring efficient and reliable flight performance.

- Industrial - Use Drones: For industrial - use drones, such as those used in surveillance, inspection, and delivery, the 8 - layer second - order circuit board is equally important. In surveillance drones, it enables the processing and transmission of real - time video feeds from high - definition cameras over long distances. In inspection drones used in industries like construction and energy, the board can interface with various sensors to collect data about the condition of structures or equipment. Delivery drones rely on the board to control the precise movement of the drone, manage the payload release mechanism, and maintain communication with the delivery network.

- Reliability and Quality

- High - Quality Materials: The 8 - layer second - order drone circuit board is constructed using top - quality materials. The laminates are selected for their excellent electrical insulation properties, mechanical strength, and ability to withstand the harsh environmental conditions that drones may encounter, such as temperature variations, vibrations, and humidity. The copper traces are of high purity to ensure low resistance and reliable electrical conductivity, which is crucial for efficient power transfer and signal transmission.

- Stringent Quality Control: The manufacturing process of this circuit board involves strict quality control measures. Each layer is precisely fabricated and inspected to ensure accurate circuitry placement. The board undergoes comprehensive electrical testing, including impedance testing, continuity testing, and signal integrity analysis. Mechanical tests are also conducted to ensure that the board can withstand the vibrations and mechanical stress during drone flights. These rigorous quality control procedures guarantee that the circuit board meets the high - reliability standards required for drone applications.

- Customization Options

- Tailored to Your Drone's Needs: Manufacturers offer a wide range of customization options for the 8 - layer second - order drone circuit board. Whether you need specific component placements to fit a unique drone form - factor, additional layers for more complex functions (such as integrating advanced sensors or communication modules), or customized routing designs to optimize performance for your specific application, the board can be tailored to your exact requirements. This flexibility allows drone manufacturers to create products that are perfectly suited to different market segments and user needs, from hobbyist drones to professional - grade industrial drones.