| Small-Batch PCB Prototyping, Customization & Rapid Solutions | Nuomai Techno |

| Date:2025-06-04 20:38:58 | Visits: |

Why has small-batch customization and rapid prototyping become the core engine of electronic innovation?

In the wave of rapid iteration in the global electronics industry, the traditional large-scale production model has become difficult to meet the diverse demands.

• Revolution in R&D Efficiency: Startups and engineering teams urgently need to quickly validate design concepts to avoid the high cost of trial and error in large-scale production. According to data from the Electronic Industries Alliance (EIA) in the United States(https://www.eia.org), using small-batch sampling can shorten the product R&D cycle by 50% to 70%, enabling innovative products to enter the market on average four months earlier.

The explosion of personalized demands: The customized demands from DIY enthusiasts, educational institutions and small and medium-sized enterprises have soared. For instance, in scenarios such as the Arduino open-source project and robot prototype development, users usually need only 5 to 500 circuit boards. The "minimum order quantity threshold" of traditional production lines has become an obstacle to innovation.

• Cost structure optimization: For unproven products, small-batch production can reduce inventory risks by over 70%. According to Prismark research, the average cost of small-batch PCB prototypes is only one-third of that of traditional mold production, making it particularly suitable for makers and research projects with limited budgets.

As a leader in the field of flexible manufacturing, PS TECH, relying on its two production bases in Shenzhen (with a total area of 20,000 square meters) and a professional team of over 500 members, offers a full-service chain from 24-hour rapid prototyping to small and medium batch customization. Nuomai has supported over 3,000 innovative projects worldwide.

II. Analysis of the Five Core Categories for Small-Batch Customization and Rapid Prototyping

1. Ultra-fast response type: 24-hour prototype verification

Nuomai Technology is equipped with advanced equipment such as LDI laser exposure machines and fully automatic electroplating lines and offers a 24-hour express prototyping service (minimum order quantity: 5 pieces). For instance, a German smart hardware team developing wireless headphones completed three rounds of circuit optimization within three days through Nuomai's 48-hour prototyping service, and the final product was mass-produced 1.5 months ahead of schedule.

Low-cost PCB prototyping, through standardized processes and the advantage of centralized purchasing, offers a starting price of $50 for 4-layer board prototyping (30% lower than the industry average). A robotics club at an Indian university purchased 100 custom boards for a competition, reducing costs by 60% compared to buying finished products. Additionally, through Nuomai's free DFM (Design for Manufacturability) analysis, they avoided three design flaws.

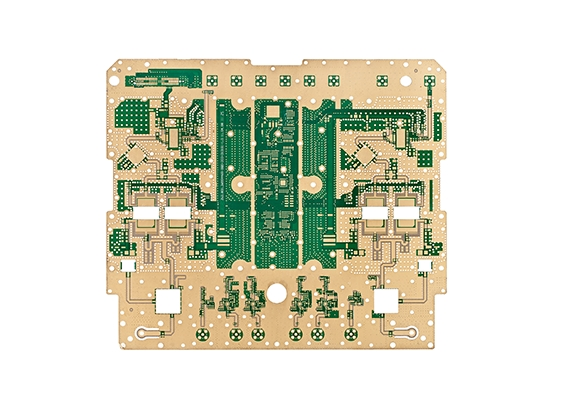

2. Customized development type: Fully flexible process adaptation

SourceURL:file:///Users/liaozh/Library/Containers/com.tencent.xinWeChat/Data/Library/Application Support/com.tencent.xinWeChat/2.0b4.0.9/786c5c584a82659ce54e293c8c082b2b/Message/MessageTemp/9e20f478899dc29eb19741386f9343c8/File/Small-Batch PCB Prototyping, Customization & Rapid Solutions Nuomai Technology.docx Our Custom PCB service supports full-category customization including single, double, and multi-layer boards, HDI boards, rigid-flex boards, etc. The minimum line width is 3mil and the minimum hole diameter is 0.15mm (FR-4 material). We customized a Robot PCB for an American maker team. It adopts an 8-layer design to integrate sensor interfaces and motor drive circuits, and is suitable for the compact space of a 30cm small robot. It has passed a 100-hour continuous operation test.

The Arduino-compatible PCB is a board specifically designed for the open-source hardware ecosystem. It supports plug-and-play modular layout and has served over 2,000 maker projects. A Japanese educational institution purchased 500 custom boards for its youth programming courses. The cost was 55% lower than that of ready-made modules, and it also supports personalized logo silk-screen printing.

3. Vertical Scene Solutions: Deep Customization in Specific Fields

The wireless charging PCB (Wireless Charging Board) adopts low-loss PTFE dielectric material and electromagnetic shielding technology, supporting a 15W+ wireless charging solution, and is compatible with smartphones and smart home devices. Nuomai provided a small batch of samples (50 pieces) for a South Korean consumer electronics brand, which passed the Qi certification test with a charging efficiency of 92%, facilitating the rapid launch of its corresponding product line.

The LED PCB (LED circuit board) with high thermal conductivity aluminum substrate supports 0201 ultra-miniature component mounting, with the minimum board thickness of 0.2mm. A domestic lighting manufacturer completed the verification of 10 types of LED filament boards through Nuomai's 3-day express sampling, and started mass production before the Christmas season, with the order volume increasing by 80% year-on-year.

4. Flexible electronics innovation: Breaking through spatial limitations

The minimum bending radius of the Flexible PCB (Flexible Circuit Board) is 0.1mm, and it can withstand over 100,000 bends. It is suitable for applications such as wearable devices and medical endoscopes. A custom-made flexible touchpad for a Shenzhen smartwatch manufacturer passed the 100,000-bend test and IP68 waterproof certification, facilitating the product's entry into the European market.

The Power PCB (power circuit board) supports thick copper process (up to 12 oz) and high-temperature resistant materials, suitable for scenarios such as new energy vehicle charging modules and industrial power supplies. A small batch order of power boards (200 pieces) from a German new energy enterprise was completed by Nuomai within 5 days through expedited production, meeting the customer's prototype testing requirements ahead of schedule.

5. One-stop value-added services: from sample making to finished products

• PCB Assembly 6 SMT production lines support 0201 component placement, BGA soldering and full-process testing, providing "bare board manufacturing + component procurement + functional testing" turnkey services. For the 100-piece prototype assembly project entrusted by an Israeli medical equipment company, through Nuomai's one-stop service, the delivery cycle was shortened by 40%, and the defect rate was controlled within 0.3%.

III. Product Matrix and Technological Barriers of Nuomai Technology's Small-Batch Customization

1. A flexible manufacturing system empowered by technology

• Equipment Cluster: Equipped with laser drilling machines (minimum hole diameter 0.08mm), flying probe testers (accuracy ±0.025mm), and AOI automatic optical inspection equipment, ensuring the precise realization of complex processes.

• Quick response mechanism: The overseas business team provides a quotation response within 2 hours, and the engineering department completes the Gerber file review within 48 hours. For urgent projects, the "green channel" can be activated for priority production scheduling.

2. Dual Assurance of Quality and Cost Efficiency

• Certification System: Certified by ISO 9001, UL, IATF 16949, etc., strictly adhering to IPC-A-610E standards, with a first-pass yield rate of over 95% for prototype boards.

Cost optimization: Our own factories and global supply chain integration enable full-process cost control from "material procurement - production - testing". The average cost of small-batch orders is 20% - 30% lower than that of our peers.

IV. From Small Batch to Scale: Growth Partners for Innovative Projects

Nuomai Technology is not only a supporter of prototype verification but also a long-term partner of innovative projects. Through the full-cycle service of "small-batch sampling - design optimization - mass production", it has helped over 500 enterprises make the leap from creativity to commercialization.

If you are looking for a reliable small batch PCB prototyping service provider, welcome to visit the official website of Nuomai Technology at www.nespcb.com and submit your design requirements. Experience the 24-hour rapid response immediately and bring your ideas to life at the fastest speed!

|

| Prev:PCB Industry Technological Breakthroughs Leading the New Revolution in Electroni Next: |